Wiring pickups, jacks, switches and potentiometers into your cigar box guitar is pretty simple, if you follow the pictorial guides provided by many of the parts manufacturers and builders.

I've incorporated some wiring options into this blog post for your benefit, and for me as well, so we don't need to catapult around Google looking for the perfect schematic for a particular job.

The grounding of the guitar is the most important thing to do correctly, after you've created good solder joints. Done right, you can have a well grounded guitar with no shielding, or you can do it wrong and have the worst sounding shielded guitar on the planet.

It is very important to ground your project so that you eliminate 'hum' (although single-coil pups tend to produce a slight hum), while humbuckers tend to be quiet.

The general rule of thumb is ground all metal parts, and that all ground wires lead to the back of the volume pot, and then one wire is run from the volume pot to the ground lug on the jack, which will eliminate the chance of producing a 'ground loop'. This means that each component can follow only one path to ground. If there is more than one path to ground, a ground loop exists.

If you are using shielding tape or foil, and you have more than one component, do not run ground wires between the components (pots for instance). Doing so will create a ground loop, because the foil acts as a ground in itself.

Most guitar schematics indicate multiple ground symbols throughout the drawing, for individual components. It is assumed that it is understood that each ground goes to a central location (the volume pot).

If you want more information on grounding and shielding, please access the following link: http://www.guitarnuts.com/wiring/shielding/shield3.php.

The grounding of the guitar is the most important thing to do correctly, after you've created good solder joints. Done right, you can have a well grounded guitar with no shielding, or you can do it wrong and have the worst sounding shielded guitar on the planet.

It is very important to ground your project so that you eliminate 'hum' (although single-coil pups tend to produce a slight hum), while humbuckers tend to be quiet.

The general rule of thumb is ground all metal parts, and that all ground wires lead to the back of the volume pot, and then one wire is run from the volume pot to the ground lug on the jack, which will eliminate the chance of producing a 'ground loop'. This means that each component can follow only one path to ground. If there is more than one path to ground, a ground loop exists.

If you are using shielding tape or foil, and you have more than one component, do not run ground wires between the components (pots for instance). Doing so will create a ground loop, because the foil acts as a ground in itself.

Most guitar schematics indicate multiple ground symbols throughout the drawing, for individual components. It is assumed that it is understood that each ground goes to a central location (the volume pot).

If you want more information on grounding and shielding, please access the following link: http://www.guitarnuts.com/wiring/shielding/shield3.php.

One HB & One Volume

One HB & One volume & One Tone

One SC & One Volume

One SC & One Volume & One Tone

Two HB & One Switch & One Volume

Two HB & One Volume & Two Tone & 3-Way Switch

Two SC & One Volume & One tone

One SC & One Volume & Ground to Bridge

(This example shows how proper grounding can eliminate a 'ground loop)

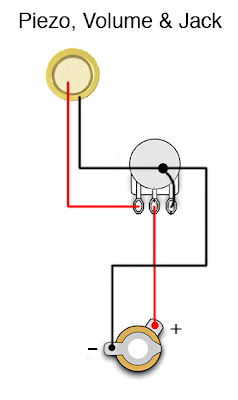

Two Piezo & Two volume & 3-Way Switch & Jack

Standard Tele Wiring

5-Way Switch

Tele Switch Plate